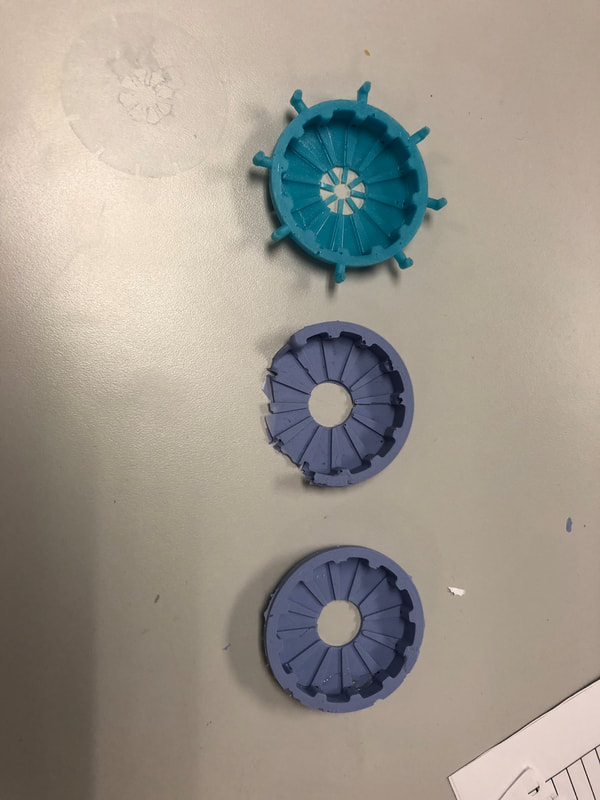

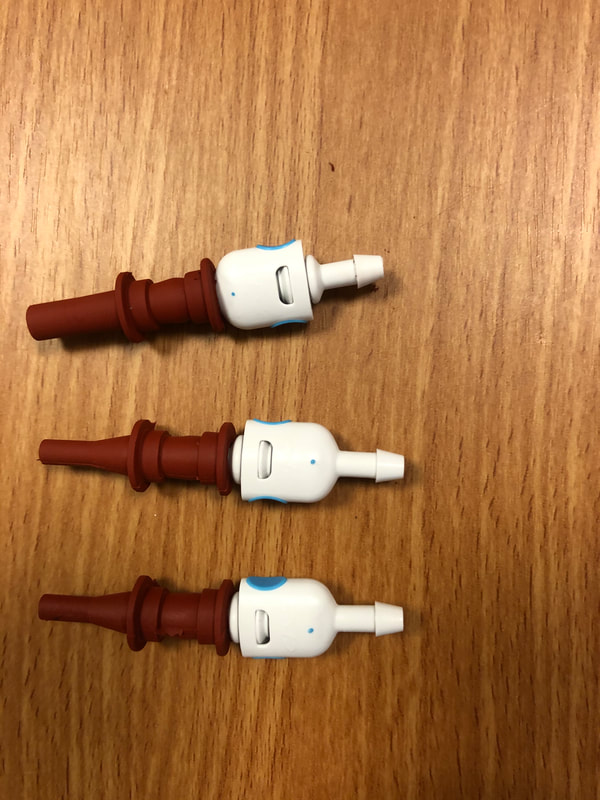

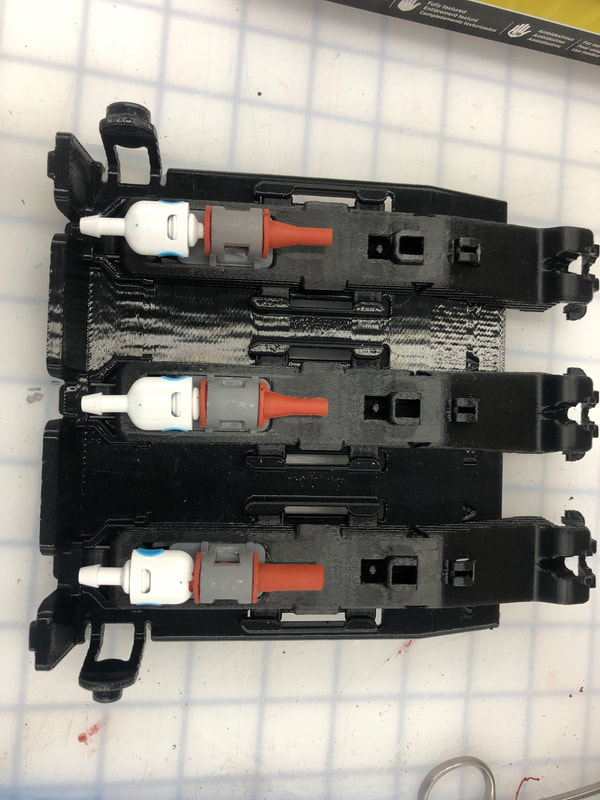

Silicone Molding

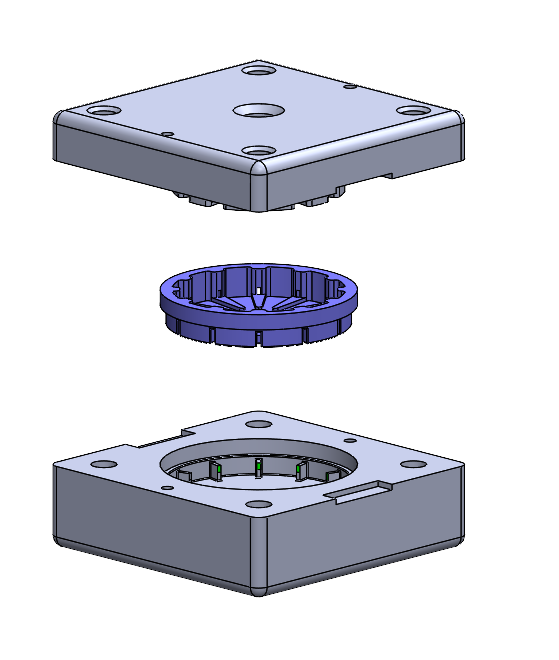

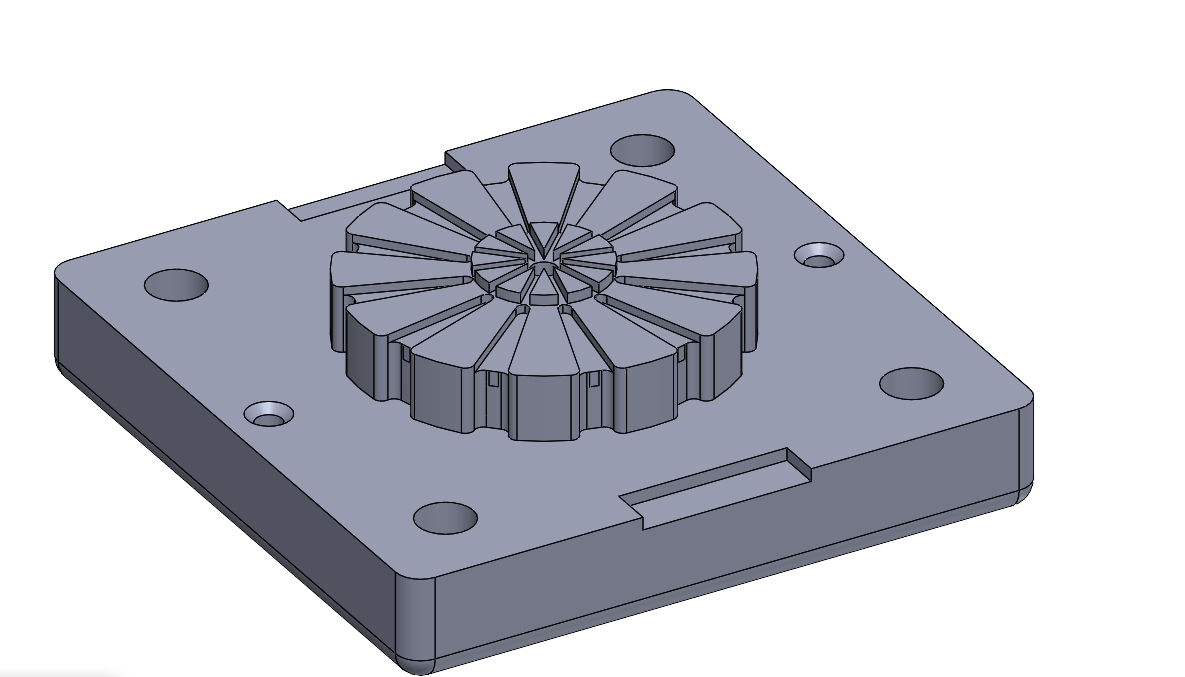

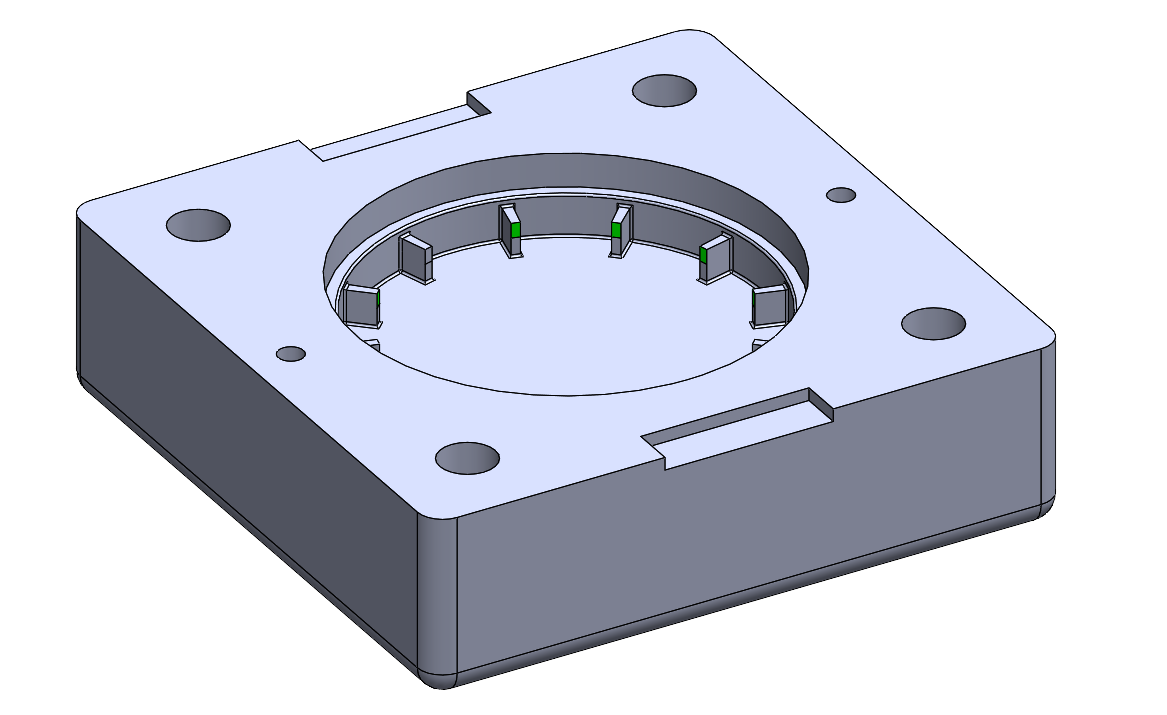

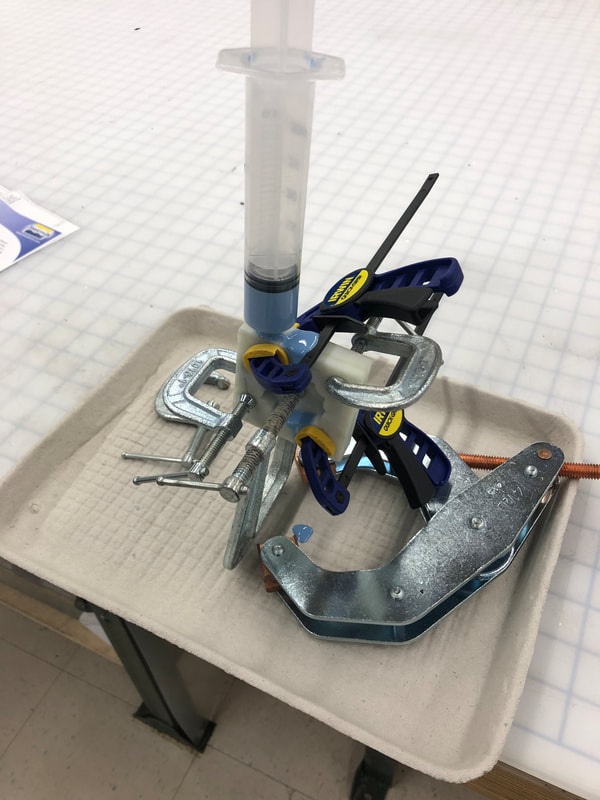

In 2018, due to a client need for quick turn silicone molding, which tends to require a >15 Day lead, I worked to develop an in house silicone molding technique leveraging a Form 2 SLA printer in combination with Smooth-On silicones. Molds use common off the shelf plastic syringes as injectors into SLA molds.

Since the investigation in 2018 and leveraging past injection molding experience, the process now can deliver functional parts in a range of durometers and grades. Typically molds can be designed in a working day and printed overnight with functional prototypes ready to test for scalability within 2 days of client approval.

While such an in house process is typically more expensive per unit that alternative options, primarily due to labor, it has become indispensable at times where speed is critical. Additionally, the in house development and understanding of pitfalls within the process has meant the labor costs have decreased significantly since 2018 and has been used on multiple other projects and applications.

Since the investigation in 2018 and leveraging past injection molding experience, the process now can deliver functional parts in a range of durometers and grades. Typically molds can be designed in a working day and printed overnight with functional prototypes ready to test for scalability within 2 days of client approval.

While such an in house process is typically more expensive per unit that alternative options, primarily due to labor, it has become indispensable at times where speed is critical. Additionally, the in house development and understanding of pitfalls within the process has meant the labor costs have decreased significantly since 2018 and has been used on multiple other projects and applications.